What Is Brazing and Why It Matters

Brazing is a metal-joining process that uses a filler metal with a lower melting point than the base metals. When heated above 450°C, the molten filler flows into the joint by capillary action, forming a strong, leak-free bond without melting the base materials.

Compared with welding or soldering, brazing offers cleaner joints, better mechanical strength, and improved corrosion resistance, making it an ideal solution for industries like HVAC, refrigeration, plumbing, and automotive manufacturing.

Types of Brazing Alloys

1. Brass Brazing Alloy

Brass brazing alloys are primarily composed of copper and zinc, sometimes with small amounts of nickel or tin to improve flow and strength.

Features and Benefits:

Working Temperature: 870–900°C

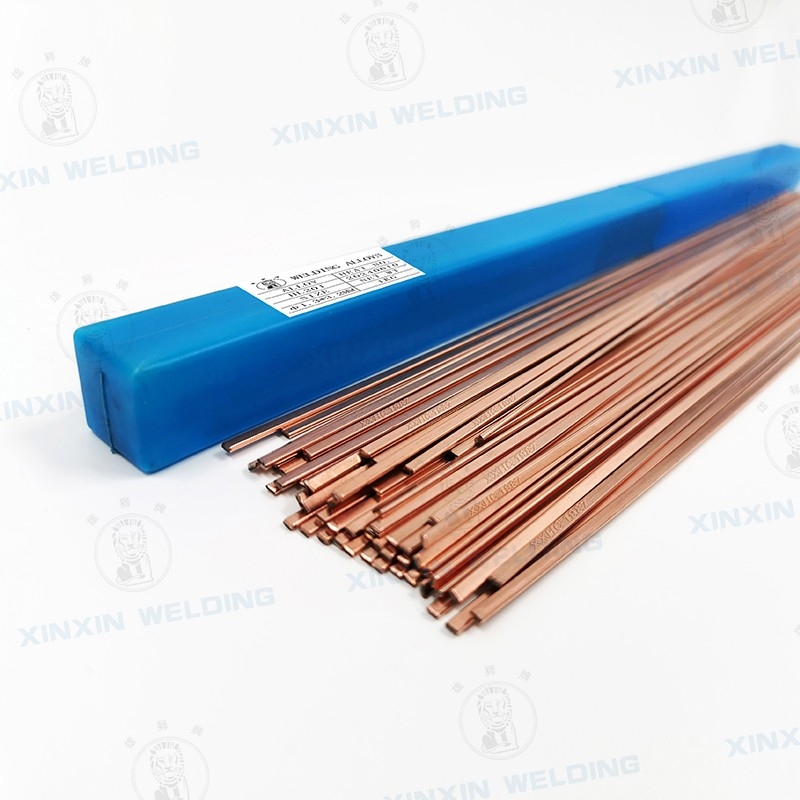

Common Forms: Rods, wires, and preforms

2. Copper Phos Brazing Alloy

Copper-phosphorus (Cu-P) alloys are widely used for copper-to-copper or copper-to-brass joints without the need for flux.

Advantages:

Working Temperature: 650–820°C

Common Forms: Rods and rings

Choosing the Right Brazing Alloy for Your Application

Selecting the correct brazing alloy depends on several factors:

For copper-to-copper joints, use Copper Phos Brazing Alloy (BCuP series) for easy flow and self-fluxing.

For steel or brass joints, choose Brass Brazing Alloy for stronger mechanical bonding.

Why Choose Us as Your Brazing Partner

At Tongling Xinxin, we focus on delivering reliable and efficient brazing solutions that meet international quality standards.

Our brazing alloys are designed to ensure:

Whether you need Brass Brazing Alloy or Copper Phos Brazing Alloy, our technical team can help you select the most suitable materials for your specific process.

Brazing is a critical technique for achieving strong and durable joints in various industries. By selecting the right brazing alloy and working with a trusted manufacturer, you can ensure higher reliability, longer service life, and better performance of your metal assemblies.